American Plastics Can Be Fun For Anyone

Wiki Article

Everything about American Plastics

Table of ContentsFascination About American PlasticsGetting The American Plastics To WorkFascination About American PlasticsThe 3-Minute Rule for American PlasticsAbout American Plastics

Bigger tasks might call for pipes with greater sizes to efficiently distribute fluids over long distances. Variables such as surface problem, the possibility for ecological stress and anxiety, and the installment atmosphere ought to influence the pipe size to guarantee an effective, long-term application.Involve with specialist guidance to validate your selection and adjust as needed for ideal outcomes. Armed with this expertise and the actionable actions outlined, you are well-equipped to make educated decisions when choosing HDPE pipeline dimensions for your jobs. Your focus to information in this selection procedure will certainly go a long way in guaranteeing the efficiency, safety and security, and cost-effectiveness of your piping systems.

American Plastics - Questions

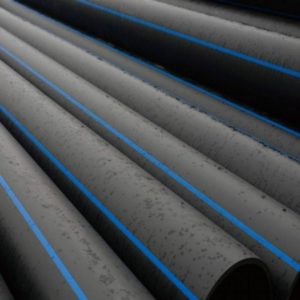

Due to the fact that HDPE is lightweight and chemically inert, it can handle liquid and gas transport with minimal upkeep. HDPE pipes are extensively adopted across a range of fields due to their adaptability and toughness. One of the most typical uses for HDPE pipe remains in supply of water systems. HDPE's corrosion resistance makes it optimal for both potable and non-potable water circulation, whether in metropolitan networks or private systems.: HDPE pipes are joined via heat blend, creating a smooth, uniform link as solid as the pipeline itself. This watertight joint is critical in gas and water distribution, where leakages can result in unsafe scenarios or costly waste.: HDPE pipes are lighter than traditional metal pipes, making them simpler to deliver and set up.

Our simple and fast getting procedure and reliable logistics ensure you get your 4-inch HDPE pipeline in the quickest feasible time (hdpe pipe fittings Midland TX). Our after-sales team is readily available 24/7 to assist with any kind of issues you may come across, guaranteeing tranquility of mind.

PE 80 is for basic commercial applications like gas and water, while PE 100 supplies long-term toughness and efficiency for tougher usages. For a succinct take a look at applications, below are several of the most usual kinds of HDPE piping and their applications. Piping systems make use of PE 32 or PE 40 for low-pressure applications.

Not known Details About American Plastics

PE 80 has a product resistant to splits, so it appropriates in applications susceptible to breaking, like sewer systems and water circulation lines. PE 100 is additionally resistant to fractures, and 100 N/mm2 is the minimum required stamina. As pointed out, classifications of HDPE piping include nominal pressure, product, and shade coding.

Suppliers produce pipes with different stress qualities (PN grades). This shows the stress in bars the pipe can sustain with water at 68 degrees Fahrenheit. The pressure qualities follow European standards, and they are: PN 2.5 max stress 2.5 bar PN 4max stress 4 bar PN 6max pressure 6 bar PN 10max pressure 10 bar PN 16max stress 16 bar The color codes that show the pressure grade are yellow for PN4, red for PN6, blue for PN10, and green for PN16.

The total list of sizes is considerable. Nonetheless, pipeline suppliers use sizing overviews with extra info like wall thickness and mass. Quality control complies with ISO criteria regulating the product layout and minimum required strength (MRS) of pipelines. Usually, high quality guarantee tests notify the makers if the HDPE pipes can supply 50-plus years of solution under typical operating problems.

Industries consider nominal stress, material, and other components when figuring out which pipelines to utilize - https://americanplastics.carrd.co/. Today, you'll see high-density polyethylene pipelines in water supply, gas distribution, agriculture, and much more.

American Plastics Things To Know Before You Get This

Mining business use pipelines for slurry transportation and dewatering. Lastly, HDPE piping can secure wires in the telecommunications industry. This is useful for underground cables. The ideal part is that businesses can make use of general PN class pipes for this application. Industries select HDPE piping over traditional pipelines since they use much more advantages.

For starters, HDPE pipelines are remarkably resilient and can last a very long time with very little upkeep. They're also immune to rust, chemicals, and UV rays. https://www.pageorama.com/?p=americanplastics. HDPE pipelines are also economical compared to various other piping materials. They're less prone to damages, which cuts fixing prices! HDPE pipes are lighter than standard pipelines for much better handling and transport.

American Plastics for Beginners

Whether you're a service provider, designer, or do it yourself enthusiast, this article will certainly give you with the expertise to make informed decisions and accomplish optimum outcomes. When basics it comes to picking the appropriate HDPE pipe for your job, understanding the PSI ranking is of utmost significance. The PSI ranking determines the toughness and stress capability of the pipe, suggesting just how much stress it can stand up to without failure.The PSI ranking of an HDPE pipe determines its capability to deal with various pressure levels. Pipelines with higher PSI scores can hold up against higher pressure, making them suitable for applications that involve higher liquid or gas stress. On the other hand, pipes with lower PSI scores are suitable for low-pressure applications.

Report this wiki page